| |

| |

| |

CERTIFICATE OF TRACEABLE CALIBRATION

anufacturer: RunSea technology

Model: RS-PJ-00M010035 / RS-PJ-00M010039 / RS-PJ-00M010036

Description: InsulationCover Set/Prs.Chamb. / InsulationCoverSet/Heat Chamb. / InsulationCoverSet/mt.staf.

Calibration Date: 2008-03-01

Runsea technology certifies the above product meets or exceeds its published specifications. Before the product being shipped out from the factory, This certificate shall not be reproduced, except in full, without the written approval of the calibration facility.

Warranty period: 1 year for the breakdown of the normal use of contract equipment (non-human factor damage, please send us back the component(s), then we shall return the new one(s) for your

personnel to replace it). All malfunctions or damages which result from the act of God or any blameable misuse are not included.

EQUIPMENT USED:

Mfg./Model |

Description |

Unit |

Due Date |

RS-PJ-00M010035 |

InsulationCover

Set/Prs.Chamb.

|

SET |

2009.03.01 |

RS-PJ-00M010039 |

InsulationCover

Set/Heat Chamb |

SET |

2009.03.01 |

RS-PJ-00M010036 |

InsulationCover

Set/mt.staf |

SET |

2009.03.01 |

|

| 保溫棉材質︰ |

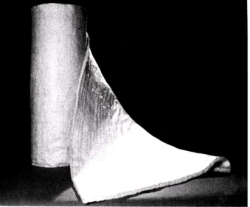

IN-AL 單面鋁箔耐熱布系列產品

基材:KM600 系耐高溫布 表面 Coating:貼鋁泊或鍍鋁

特性:優良之熱反射,耐油水,氣密性

符合中華民國 CNS 10285/A2 一級耐燃標準

應用範圍:防火服, 防火毯, 隔熱遮簾 防熱圍裙, 保溫布包

IN-AL Aluminum/Fiberglass Cloth

The IN-AL series are made of fiberglass cloth with aluminum foil laminated or aluminization on one side for heat reflectivity. FEATURES of IN-AL fabrics are:

light weight, soft and pliable light weight, soft and pliable

very low flamibility or flame retarded very low flamibility or flame retarded

good surface cleaness good surface cleaness

oil, water and moisture resistant oil, water and moisture resistant

good adhesion between aluminum/aluminized and the base glass cloth good adhesion between aluminum/aluminized and the base glass cloth

|

|

Technica Data

產品代號

Product ID

|

鋁面

Surface |

厚度Thick(mm) |

單位面積重

Areal weight (g/m2) |

張力強度

Tensile StrengthKg/cm |

耐溫

Temperature limit (oC) |

每捲呎吋

Roll sizes

(寬x長) (m) |

2-32L/M |

Aluminization |

0.23 |

323 |

49x45 |

200 * |

1.42x91 |

4-43L/M |

Aluminization |

0.4 |

434 |

53x44 |

200 * |

1.5x45 |

4-46L/M |

Aluminization |

0.45 |

460 |

110x70 |

200* |

1.0x50

1.5x50 |

4-49L/M |

Aluminization |

0.4 |

490 |

100x60 |

200 * |

1x50

1.5x50 |

6-710L/A |

Aluminum

Foil |

0.6 |

710 |

91x100 |

200* |

1x50 |

8-62H/M |

Aluminization |

0.8 |

620 |

35x17 |

200 * |

1.37x45 |

8-66H/A |

Aluminum

Foil |

0.8 |

662 |

44x44 |

230 ** |

1.5x45 |

10-74H/M |

Aluminization |

1.0 |

740 |

35x44 |

200* |

1.5x45 |

16-100L/A |

Aluminum

Foil |

1.6 |

1000 |

-- |

230 ** |

1x30 |

|

| |

|

| |

|

IN-Fluo 鐵氟龍塗佈玻纖布系列

基材:KM600 系耐高溫布

表面:PTFE (鐵氟龍)COATING

耐溫:287℃

特性:抗化學品,具彈性及氣密性, 耐油水,耐候, 防沾黏, 潔淨表面, 防火

應用範圍:膨脹接頭, 防震接頭, 保溫夾克, 伸縮蛇管, 無塵室保溫 |

|

| |

|

|

|

|

Data and Availability

產品

Product ID |

厚度

Thickness

(mm) |

單位面積重

Areal Weight

(g/m2) |

張力強度

Tensile Strength

(N/50mm) |

每捲呎吋

Roll sizes (m) |

3-43P/P |

0.3 |

425 |

2670x2220 |

1.5x45.7 |

4-56P/P |

0.43 |

560 |

3660x3170 |

1.5x45.7 |

4-61P/P |

0.46 |

610 |

3660x3170 |

1.5x45.7 |

9-115P/P |

0.86 |

1153 |

5400x4600 |

1.5x45.7 |

|

| |

|

| |

|

KM600 & KM1000

Needled BLANKET

(CERAMIC FREE INSULATION)

Introducing a revolutionary insulation blanket composed of long length continuous filament high temperature fiber. Fibers are non-respirable and safe to use without protective clothing. The needled blanket is pliable, resilient and easy to fabricate.

APPLICATIDNS INCLUDE: Pipe Wrap, Mold Wrap,

Stress Relieving Insulation, Gaskets, and Insulation Blankets...

INDUSTPIES: Petrochemical - Steel - Aluminum

Power Generation-Foundries-Glass-Automobile

|

|

Technical Data

Properties |

KM600 |

KM1000 |

Material |

E-grade fiberglass |

Non-amorphous silica fiber |

Composition |

SiO2 |

55% |

SiO2 |

94-96% |

CaO |

18% |

CaO |

-- |

Al2O3 |

16% |

Al2O3 |

3-4% |

MgO+B2O3 |

7% |

MgO+B2O3 |

-- |

Continuous application temperature oC |

600 |

1000 |

Peak Temperature oC (soften or melting) |

820 |

1650 |

Thermal Conductivity

(W/m.k.) |

100 oC |

0.42 |

115 oC |

0.045 |

293 oC |

0.63 |

315 oC |

0.088 |

450 oC |

0.80 |

450 oC |

0.121 |

565 oC |

0.90 |

650 oC |

0.200 |

Nominal Density (Kg/m3) |

165 +/- 20% |

140 +/-20% |

Thickness (mm) available |

3, 5, 6, 8, 10, 13, 25 |

6, 8, 10, 13, 25 |

Standard Width (m) |

1.2 |

1.0 |

|

|

| |

|

High Temperature Sewing Thread

DESCRIPTION AND ADVANTAGES:

KM600 sewing threads have been specifically designed to replace various types of synthetic and asbestos sewing threads for application at elevated temperature and have been designed specifically for use on removable and reusable insulation jackets, curtains, compensators.

KM600 sewing threads are coated with mainly PTFE lubricant to improve handling

characteristics. All Teflon coated sewing threads will not burn or support combustion in normal atmospheres. They are unaffected by fungi and impervious to acids and alkalis. |

|

|

|

| |

|

PROPERTY |

755-12 |

755-18I |

721-70 |

753-12 |

GT-12 |

GT-18 |

GT-24 |

Fiber

| Beta/BC

Fiberglass

|

Beta/BC

Fiberglass |

Kevlar |

Beta/BC

Fiberglass |

Fiberglass |

Fiberglass |

Fiberglass |

Diamater

(inch) |

0.016 |

0.019 |

0.01 |

0.015 |

0.016 |

0.019 |

0.023 |

Tensile

Str./Lb |

12 |

20 |

20.5 |

12 |

20 |

25 |

29 |

Yards/Lb |

2500 |

1530 |

2950 |

3000 |

2950 |

1975 |

1475 |

Reinforced |

Stainless

steel |

Inconel |

Stainless

Steel |

-- |

-- |

-- |

-- |

Type of

Coating |

Teflon |

Teflon |

Teflon |

Teflon |

Teflon |

Teflon |

Teflon |

Coating % |

12 |

12 |

12 |

12 |

15 |

15 |

15 |

Temperature

resistance |

1000oF |

1000 oF |

1000oF |

1000oF |

1400oF |

1400oF |

1400oF |

|

| |

| |

| |

| |

PROPERTY |

GT-27 |

GT-18I |

GT-18S/S |

RE-760-S |

P1320 |

P1500 |

NL-1/2 |

Fiber |

Fiberglass |

Fiberglass |

Fiberglass |

35% Cotton

Jacketed |

PTFE |

PTFE |

Kevlar®

(aramid) |

Diamater |

0.031 |

0.019 |

0.019 |

0.018 |

0.01 |

0.01 |

0.01 |

Tensile

Str./Lb |

40 |

25 |

25 |

8 |

8 |

6.7 |

12 |

Yards/Lb |

920 |

1975 |

1975 |

1800 |

3400 |

3030 |

8400 |

Reinforced |

-- |

Inconel® |

Stainless

steel |

65% V2A

-Stainless Steel |

-- |

-- |

-- |

Type of

Coating |

Teflon |

Teflon |

Teflon |

-- |

-- |

-- |

-- |

Coating % |

15 |

15 |

15 |

-- |

-- |

-- |

-- |

Temperature

resistance |

1400oF |

1400oF |

1400oF |

1100oF |

500oF |

500oF |

500oF |

|

Kevlar® : registered trademark of DuPont Inconel®: registered trademark of INCO family of companies

All statements herein are expressions of opinion that we believe to be accurate and reliable, but are presented without guaranty or responsibility on our part. Statements concerning possible use of our products are not intended as recommendations for their use alone or in combination with any materials or elements to infringe any patents. No patent warranty of any kind, express or implied, is made or intended. |

|

THERMOCOAT® 熱魔克(高溫斷熱夾克) |

|

本公司引進高性能非石棉耐高溫布料並研發專業 加工技術,將保溫工事模組化,用各種耐高溫布料不 同之特性做內裡和外覆;內填充玻璃纖維針軋毯、岩 棉或陶瓷纖維毯等;或可以用於填充在夾層之保溫斷 熱材料;利用車縫或夾扣之方式加工製作

而成;再以 金屬或塑膠扣具安裝固定於機械或管件上以達到我們 要求的保溫效果,可以被設計安裝於各種外表複雜之 設備上。 |

其特性如下:

1. 安裝容易,並可重覆多次使用:

傳統保溫施工, 大部分以保溫棉毯或保溫管材使用保溫釘具固定後外披覆金屬薄皮;部份管路上的閥件、法蘭、人孔,或非制

式管路或設備因保養或其它因素拆卸卻無法即時復原造成高溫設備裸露,可能使人員燙傷和讓能源流失。 THERMOCOAT®

熱魔克;以耐高溫布車縫而成以 金屬鉤、粘扣帶、束帶、等固定於夾克表面;設備 維修時拆裝迅速且不需要專業人員即可作業。

2. 施工時間短,減少於現場施作工時:

從量尺寸到安裝完工,將其生產於工廠模組化完成 後再到現場安裝;不在現場製作減少進場工時及施 工時間。

3. 耐高溫、斷熱效果優良:

多種耐高溫布料可以選擇範圍從-60℃~1300℃;多種 耐高溫纖維毯做填充材,其熱傳導率在400℃為 0.03~0.09 Kcal/mh℃,斷熱效

果好,可節省能源消 耗,降低生產成本。

4. 耐候性、防水、防油、持久性,安全性:

多種耐高溫保溫布可以選擇;外塗佈高性能塗料,如 SILICON,PTFE,VERMICULITE, ALUMINIZED 以達到防油,水性,耐酸鹼、

抗紫外線及幅射熱之性能;且不含石棉質避免 纖維飛散造成安衛問題。

5. 彈性化多材層設計;適用於多種環境:

超過百種的布材和保溫斷熱材可以被選擇使用,可以組合多種布料及斷熱材料及多材層設 計;適用於一般或嚴苛的環境。

|

保溫夾克使用材料表

|

材料名稱 |

材質 |

耐溫度 |

備註欄 |

| FIBERGLASS CLOTH |

E-GRADE GLASS FIBER |

550℃ |

|

| FIBERGLASS CLOTH |

E-GRADE GLASS FIBER |

230℃~

750℃ |

加矽膠塗層

加 PTFE 塗層

加 Vermiculite塗層

Aluminized 鍍鋁 |

| Kevlar®長纖布 |

ARAMID FILAMENT FIBER |

300℃ |

無塵室專用 |

| Nomex®長纖布 |

ARAMID FILAMENT FIBER |

300℃ |

無塵室專用 |

| ALUMINA CLOTH |

ALUMINA SILICA FIBER |

1200℃ |

無塵室專用 |

| CERAMICS CLOTH |

CERAMIC FIBER |

800℃ |

夾不銹鋼絲補強 |

| SILICA CLOTH |

AMORPHOUS SILICA FIBER |

1000℃ |

|

| FIBERGLASS FELT |

E-GRADE GLASS FIBER |

550℃ |

|

| SILICAFIBER FELT |

AMORPHOUS SILICA FIBER |

1000℃ |

|

| FUME SILICA |

SILICA POWER |

1000℃ |

|

| CERAMIC BLANKET |

CERAMIC FIBER |

1260℃ |

|

| SILICON SPONGE |

SILICON |

|

|

| WIRE MESH |

SUS304 |

750℃ |

|

| ALLOY 601 車縫線 |

NICKEL CHROME ALLOY |

|

|

| #304 不銹鋼車縫線 |

SUS304 |

800℃ |

|

| #316 不銹鋼車縫線 |

SUS316 |

|

|

| ALUMINA 車縫線 |

ALUMINA SILICA FIBER |

1200℃ |

|

| Rastex® 車縫線 |

PTFE |

300℃ |

|

| 耐熱,耐化學性車縫線 |

ARAMID |

300℃ |

|

Rastex®, 為美商戈爾公司之註冊商標。

Kevlar®, Nomex® 為杜邦公司之註冊商標。

|

THERMOCOAT®-ATN 潔淨級保溫夾克 被設計於專用於無塵室之保溫夾克,精挑細選出不會產生粉塵及顆粒的布料 經實驗室以 CNS 10285 驗證為一級防火布;以細工車縫製成夾克,用於安裝管路 或機台,讓優良的斷熱效果以減少溫度的散失達節省能源的目的。 模組化設計依管路尺寸製作編號,非專業人士即可安裝;並可以重複使用, 所有材料皆為不燃且通過一級防火測試;具優良的隔熱效果以管件溫度 300℃; 保溫厚度 25mm;環境溫度 26℃;無風速為例得下列數據: |

HOT FACE |

PIPE DIA, |

COLD FACE |

HEAT LOSS(W/M2) |

100℃ |

300mm |

37℃ |

117 |

200℃ |

300mm |

54℃ |

306 |

300℃ |

300mm |

75℃ |

536 |

|

| |

| |

THERMOCOAT®-FB Fire Blanket 防火毯

本產品係以二氧化矽纖維布車縫 製成,完全不 燃耐溫可達1130℃,融點為 1650℃;可做為電焊 切 割防火毯緊急滅火逃生毯之用。可依需求訂製其它呎吋,或 針對特殊用途提供設計及製作; 電焊防火毯四邊均加釘金屬環方 便懸掛或連接 滅火逃生毯上緣均加兩個提把方便滅火及逃生時包覆身體。

標準尺寸:1.2mmx914mm(布寬)X1000mmL,2000mmL,3000mmL

(可依客戶所需求之尺寸縫製)

|

|

| |

| |

THERMOCOAT®-TT Tadpole tape P 形爐門密封帶

P 型填縫耐熱帶,係以 THERMOTEX-1000 之耐熱布或 其它耐高溫布類做外層,包覆同樣材質之耐高溫之圓繩 所製成者;由於其柔軟及高壓縮性,THERMOTEX-1000 P 型帶適用於表面粗糙或螺栓栓緊力較小之法蘭面及縫 隙較小斷面。 |

|

|

|

|

|